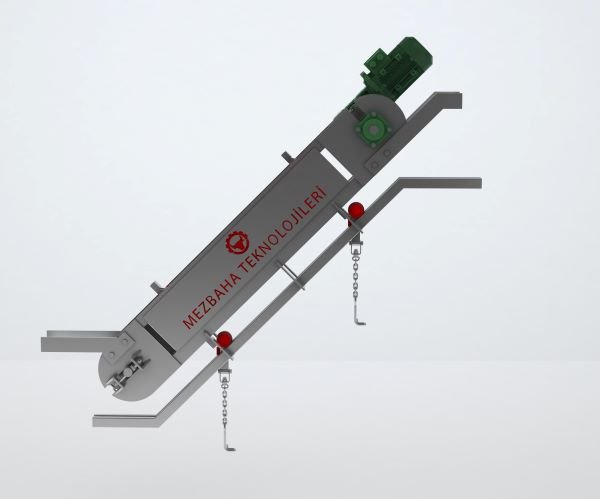

Used for transferring the sheep meat to bleeding lines in slaughterhouses. The hook of sheep bleeding elevator is attached to the one leg of the animal, and it’s replaced to the rail. The pallets of the elevator raise the hook and the sheep to the bleeding line. It is generally used for twinrails or monorails of 2400mm or 3000mm in height in slaughterhouses. Slaughterhouse machine are manufactured with galvanized or stainless material to be durable against the corrosion.

Sheep bleeding elevator will be stainless twinrail or monarail.

The folds of the chassis will be manufactured from NPU profile so as not to interfere with the movement of the chain.

With the help of propellant lugs placed on the sheep bleeding elevator chain at distances of about 600 mm, it will raise the sheep to about 2400 mm with a slope of 45 degrees.

The sheep bleeding elevator will be driven by a 2 HP power engine and infinite screw motor reducer. The speed will be about 22mt/min.

One of the chain gears will provide movement from the motor-gearbox through the chain gear.

The other gear is a tensioning gear and will be mounted on the tail part of the chassis.

Gears will be connected to the chassis with bearings.

Elevator will be mounted to corridor twinrail in drive section, and to the ground in tail section using special pins.

The body will be manufactured hot-dip galvanized material, the gear and chains will be manufactured with electrogalvanized material.